Starting a French fries production business can be highly profitable as global demand for frozen and ready-to-cook potato products continues to grow.

Success depends on planning, quality control, and choosing the right production process and equipment.

Below is a clear, step-by-step guide covering everything from research to distribution.

1. Conduct Market Research

Before investing, understand your target market.

Focus on:

Consumer taste preferences (thin, crinkle-cut, wedges, seasoned)

Demand volume (retail vs foodservice)

Competitor pricing and positioning

Industry growth trends

This helps determine:

Product type

Brand positioning

Entry strategy

2. Create a Detailed Business Plan

A structured plan reduces risk and improves investment decisions.

Include:

Cost budget

Raw materials (potatoes)

French fries processing equipment

Factory rent & utilities

Labor and packaging

Operational planning

Production capacity

Profit margins

Marketing strategy

Risk analysis & solutions

3. Select Location & Build the Factory

Choose a site that supports efficient production and distribution.

Key considerations:

Close to potato supply sources

Transportation access

Labor availability

Environmental compliance

Food safety zoning requirements

Design the facility according to food safety standards and clean production workflow.

4. Purchase Equipment & Raw Materials

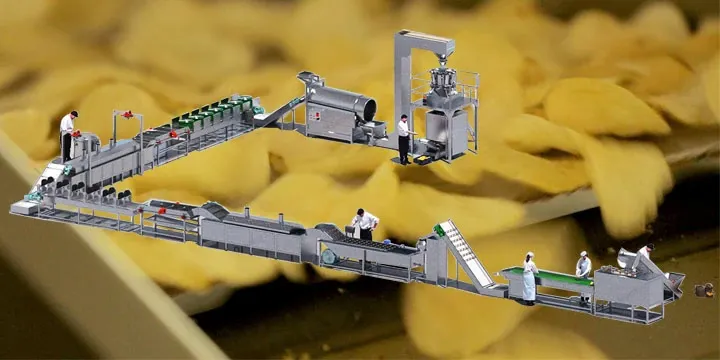

A standard French fries production line typically includes:

Washing & peeling machine

Cutting machine

Blanching machine

Frying machine

De-oiling system

Freezing equipment

Packaging machine

Ensure stable supply of high-quality fresh potatoes — raw material quality directly affects taste, color, and yield.

5. Product Development & Trial Production

Develop products based on customer demand:

Straight cut

Crinkle cut

Wedges

Seasoned varieties

Conduct pilot production to:

Adjust frying temperature

Optimize blanching time

Improve texture and flavor

Stabilize product quality

6. Obtain Licenses & Certifications

Legal compliance is essential in food manufacturing.

Typical requirements:

Business license

Food production permit

Health inspection approval

Recommended certifications:

HACCP

ISO food safety system

These increase trust and enable large-scale distribution.

7. Build a Marketing Strategy

Use both online and offline sales channels.

Online channels

Social media marketing

E-commerce platforms

Brand website

Offline channels

Supermarkets

Restaurants & fast-food chains

Food distributors & wholesalers

Attractive packaging and branding significantly improve product recognition.

8. Establish Distribution & Cold Chain Logistics

Frozen French fries require temperature-controlled transportation.

Important elements:

Cold storage warehouse

Refrigerated transport

Fast delivery routes

Distributor partnerships

A reliable logistics system ensures product quality and shelf life.

9. Implement Quality Control

Maintain consistent standards through:

Raw material inspection

Regular product testing

Process monitoring

Customer feedback collection

Continuous improvement increases customer retention and brand reputation.

10. Legal & Financial Management

Operate the business sustainably by managing:

Regulatory compliance

Tax planning

Cost control

ROI evaluation

Professional accounting and legal consultation is strongly recommended.

French Fries Production Line for Startups

Every stage — from research to distribution — requires careful execution.

Working with experienced equipment suppliers or food industry consultants can reduce startup risks and shorten the learning curve.

Conclusion

Launching a French fries manufacturing business involves more than just buying equipment. It requires market insight, proper factory planning, reliable raw materials, and a strong distribution network.

With a structured plan and strict quality control, you can build a scalable and profitable frozen potato products brand in the growing snack industry.