A cost-effective semi automatic frozen French fries production line designed for small and medium-scale factories.

With output capacities from 30 kg/h to 300 kg/h, this line offers flexible configuration, low investment cost, and stable processing performance. Suitable for frozen French fries, fried fries, and potato chips production.

The Semi Automatic Frozen French Fries Production Line is an economical and practical solution for small and medium-scale frozen French fries manufacturers. It combines reliable processing performance with flexible semi-automatic operation, making it ideal for businesses looking to enter or expand in the frozen French fries market with controlled investment.

Compared with fully automatic lines, this semi-automatic French fries production line offers similar core processing steps while keeping equipment size compact, energy consumption low, and maintenance simple.

This semi automatic frozen French fries line is available in multiple output capacities to meet different production demands:

30 kg/h

50 kg/h

70 kg/h

100 kg/h

200 kg/h

300 kg/h

Production capacity and process flow can be customized according to your factory size, budget, and product requirements.

Applicable raw materials:

Potatoes

Sweet potatoes

Carrots

Cassava

Other root vegetables

Final products:

Frozen French fries

Fried French fries

Sweet potato fries

Potato chips (with optional seasoning machine)

The semi automatic frozen French fries production line typically includes:

Potato washing and peeling machine

Strip cutting machine

Washing & blanching machine

De-watering machine

Deep frying machine

De-oiling machine

Quick freezing machine

Sealing and packing machine

Equipment can be added, removed, or replaced based on your specific needs.

Low initial investment and high return potential

Semi-automatic operation for flexible production control

Compact line design with small footprint

Low energy consumption and stable performance

Easy operation, cleaning, and maintenance

All equipment made of food-grade 304 stainless steel

French fries size adjustable from 2–10 mm

Multiple heating options: electric, gas, or combined heating

Processing capacity and equipment layout customized

Voltage and electrical system matched to local standards

Factory floor plan designed based on your workshop size

One-stop turnkey project solution available

Technical guidance provided for installation and operation

Seasoning machine (for potato chips production)

Additional freezing equipment

Customized packaging systems

This line can be upgraded to produce fried potato chips by adding a seasoning machine.

Frozen French fries have strong and growing demand in:

Quick service restaurants (QSR)

Restaurants and food chains

Bars and pubs

Airline and railway catering services

Retail frozen food markets

This makes the semi automatic frozen French fries production line a reliable long-term investment.

–18°C: Until expiration date on packaging

–12°C: Up to 1 month

–6°C: Up to 1 week

Once defrosted, do not refreeze

If you are looking for a flexible, economical, and scalable frozen French fries production solution, this semi-automatic line is the ideal choice for starting or expanding your French fries business with confidence.

We make things easy, reliable, and professional.

Weekly Updates: We’ll send you photos and progress reports every week.

Ready to Use: Every machine is fully built and tested for 2 hours before it leaves our factory.

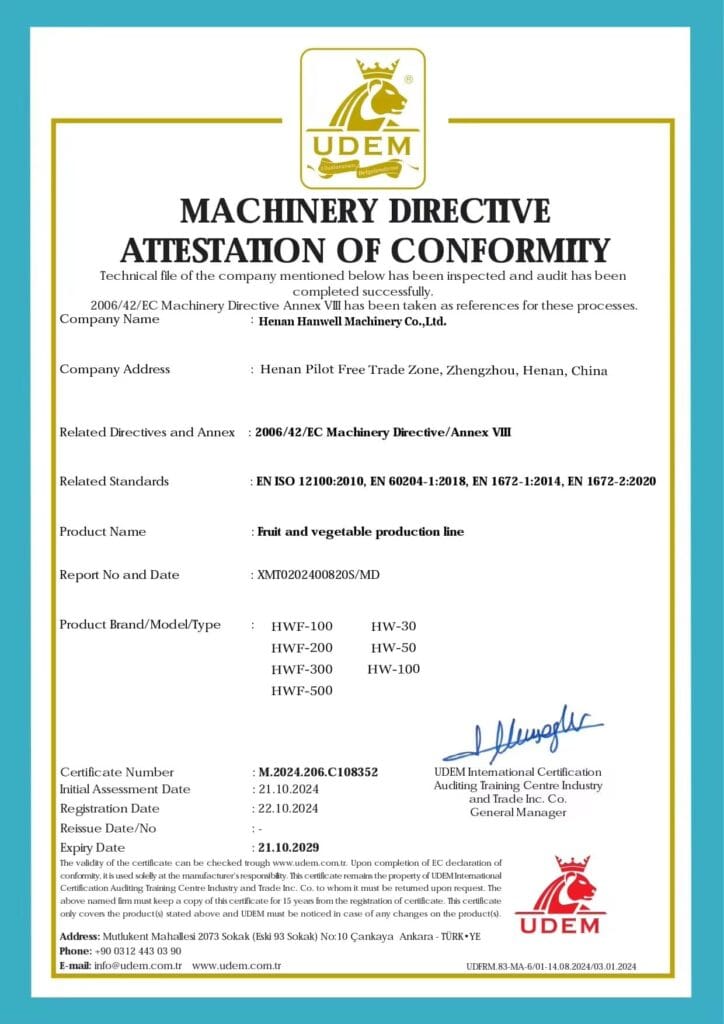

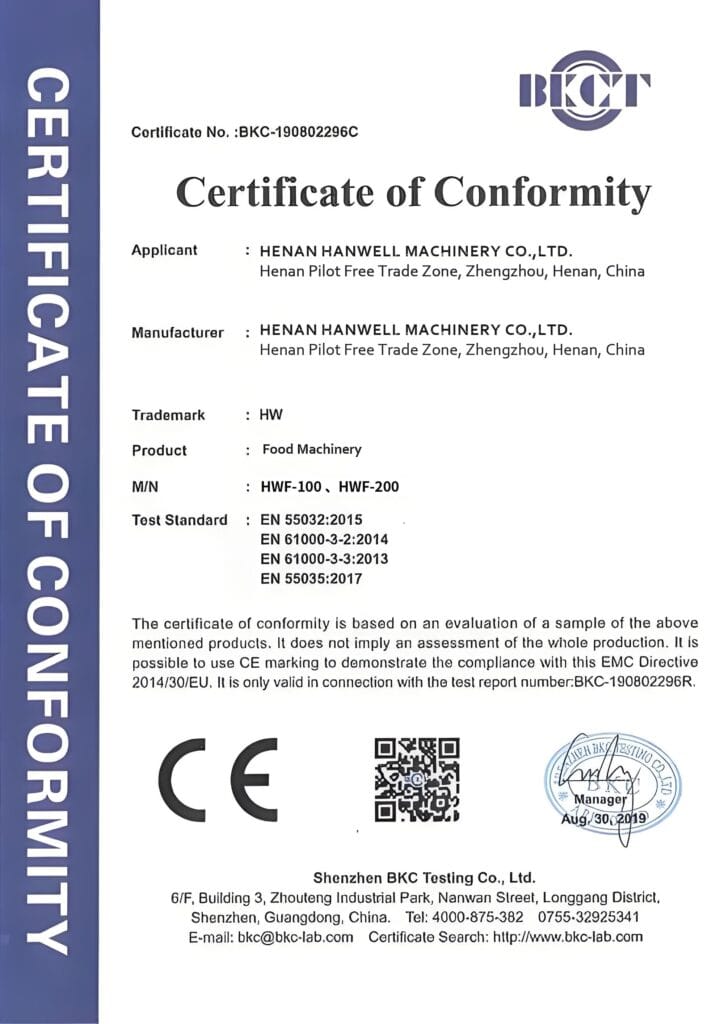

High Quality: Made entirely of top-grade stainless steel (SUS304). You are welcome to hire a third party to inspect it.

24/7 Support: We provide clear English manuals and 24-hour online help.

Expert Setup: If you need help, we can send our engineers to your site.

Future Growth: We offer OEM services, quarterly deals, and help for local agents to find customers.

Real Partnership: We visit our top clients every year to ensure your business is thriving.

Fast, customized solutions for your food production line. Talk to our experienced engineers and get a no-obligation quote today.

We respect your privacy — your info is safe and only used to provide your quote.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!