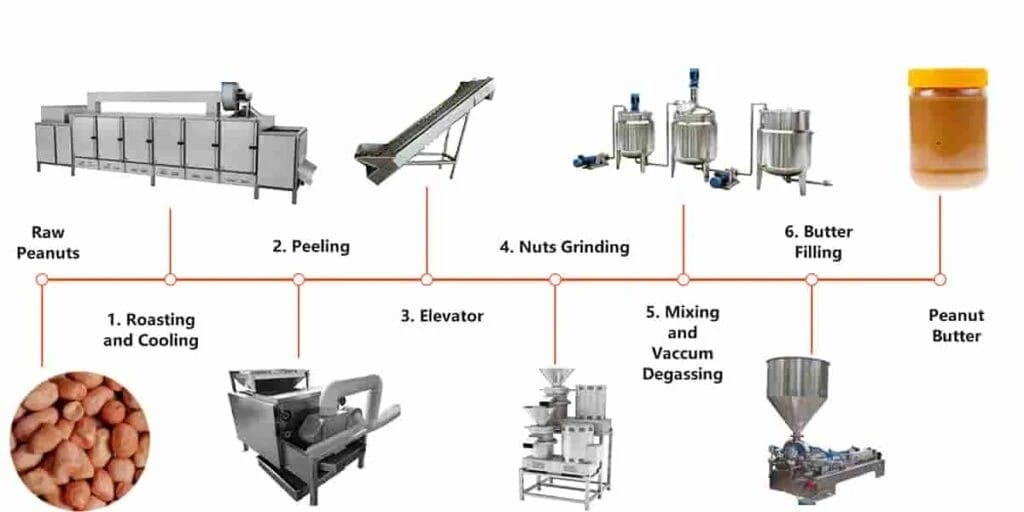

Peanut Butter Production Line

Capabilities: A complete industrial solution covering roasting, peeling, grinding, mixing, degassing, filling, and labeling.

Applications: Ideal for peanuts, cashews, almonds, sesame (tahini), and other nuts.

Capacity: 100kg/h – 1,000kg/h+ (Customizable to your requirements).

Our comprehensive nut butter processing plant offers a seamless, turn-key solution—from raw materials to retail-ready finished products. Each line is custom-engineered based on your factory layout, packaging preferences, and production goals.

The plant integrates high-performance machinery for every stage: Roasting → Cooling → Peeling → Grinding → Mixing → Vacuum Degassing → Filling → Labeling

| Feature | Details |

| Raw Materials | Peanuts, Cashews, Almonds, Sesame (Tahini), etc. |

| Capacity | 100 kg/h (Small-scale) to 1,000+ kg/h (Industrial automatic) |

| Material | Food-grade Stainless Steel 304/316 |

| Roaster Heating | Electric or Gas options available |

| Packaging | Plastic/Glass jars, Stand-up pouches, Sachets, PP containers |

| Voltage | 380V/50Hz (3-Phase), 220V/50Hz (Single), or Customized |

Our production lines are engineered for high-efficiency processing across a wide range of popular nut and seed products:

Nut Butters: Peanut, Cashew, Almond, Hazelnut, and Macadamia.

Seed Pastes: Sesame Tahini and Sunflower seed butter.

Savory Spreads: Traditional Hummus and specialized bean pastes.

The core Nut Butter Grinder (Colloid Mill) is a versatile workhorse, capable of processing more than just nuts. Its precision grinding technology is ideal for:

Plant-Based Milk: Almond milk, soy milk, and oat milk.

Confectionery: Premium cocoa liquor and chocolate mass.

Condiments: Fine spice pastes and chili sauces.

Specialty Processing: Bio-emulsions and fine-grinding of soft bone materials (fish/shrimp) for high-calcium food additives.

Our Automatic Nut Roaster integrates roasting and cooling in a single high-efficiency unit.

Precision Control: Fully adjustable temperature and timing ensure uniform color and consistent flavor profiles.

Heating Options: Available in Electric or Gas heating to suit your energy needs.

Design: Built for energy savings, easy sanitation, and long-term durability.

Designed for post-roasting processing, our Peanut Peeling Machine achieves industry-leading results.

Superior Performance: Features a high peeling rate with minimal kernel breakage.

Dust-Free Operation: Optional Integrated Skin Collection System keeps your production facility clean and compliant with hygiene standards.

The heart of the line, this professional-grade grinder is engineered for ultra-fine emulsions.

Ultra-Fine Texture: Delivers fineness up to 100 mesh, ensuring a smooth, premium mouthfeel.

Versatility: Capable of processing everything from peanut and cashew butter to soy milk and cocoa liquor.

Homogenization: Combines grinding and emulsifying in one step for maximum efficiency.

Finalize your product with our specialized tank systems.

Customizable Mixing: Add flavors and ingredients in tanks ranging from 50L to 1,000L+. Tailored to your specific recipe requirements.

Vacuum Degassing: Effectively removes air bubbles from the butter, resulting in a silky, glossy appearance and extended shelf life.

We provide fully customizable solutions. Below are the specifications for our standard 200kg/h production line:

| Equipment Name | Dimensions (mm) | Power Consumption |

| Commercial Nut Roaster | 3000 * 2200 * 1700 | 2.2 kW |

| Feeding Conveyor | 5000 * 900 * 850 | 1.1 kW |

| Cashew/Peanut Peeler | 1900 * 800 * 1400 | 1.85 kW |

| Industrial Nut Mill | 830 * 440 * 1100 | 15 kW |

| Butter Pumping System | 1500 * 250 * 250 | 1.5 kW |

| Butter Cooling Machine | 1000 * 1000 * 1700 | 2.2 kW |

| Semi-Auto Filling Unit | 400 * 400 * 1400 | 1.1 kW |

High Automation: Reliable, mechanized systems reduce labor costs.

Precision Engineering: Low-noise, stable operation with corrosion-resistant materials.

Exceptional Quality: Produces smooth, granulated, or pure nut butters to meet market standards.

Versatile Design: Easily reconfigurable to process sesame, rapeseed, almonds, and cashews.

One-Stop Factory: Full R&D, manufacturing, and quality control under one roof.1

Proven Reliability: Decades of experience ensuring stable machinery performance.

Punctual Delivery: Optimized logistics to meet your project timelines.

Warranty: 12-month quality guarantee with lifetime technical support and spare parts availability.

Training: Free online or offline training sessions at our facility.

Global Installation: On-site installation and commissioning at your factory.

Business Consulting: Expert guidance for new business planners to optimize ROI.

Logistics: Comprehensive delivery services directly to your country.

Whether you are a startup or a global manufacturer, we have the right fit:

Small-Scale: Compact roasting, peeling, and grinding units for boutique production.

Industrial-Scale: Fully automated lines reaching 1,000kg/h and beyond.

Multi-Product Customization: If you plan to produce multiple products on a single line, we can design a hybrid solution tailored to your needs.

Fast, customized solutions for your food production line. Talk to our experienced engineers and get a no-obligation quote today.

We respect your privacy — your info is safe and only used to provide your quote.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!