A potato chip making machine is a complete solution for producing one of the world’s most popular snacks efficiently and consistently. As global demand for crispy, high-quality potato chips continues to rise, food manufacturers are increasingly investing in automatic and semi-automatic potato chip production lines.

Whether you are a startup, a growing snack brand, or a large-scale food factory, choosing the right machine directly affects product quality, operating cost, and long-term profitability.

In this guide, we’ll explore different types of potato chip machines, key features, technical specifications, FAQs, and how to select the right solution—explained in a clear, easy-to-understand way.

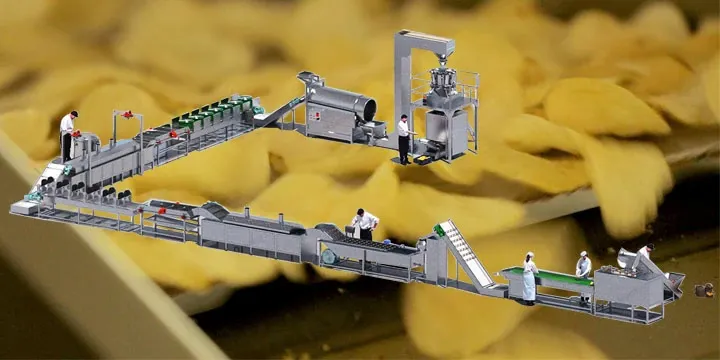

Automatic Potato Chip Making Machine

Automatic Potato Chip Production Line

An automatic potato chip production line is a fully integrated system that handles the entire process—from potato washing and peeling to slicing, frying, seasoning, and packaging. It is the ideal choice for manufacturers focused on high output and consistent quality.

Why Choose an Automatic Line?

Significantly reduces labor costs

Ensures uniform chip thickness and flavor

Supports continuous, large-scale production

Easy to integrate with packaging systems

Typical Applications

Industrial snack manufacturers

Export-oriented potato chip factories

High-output food processing plants

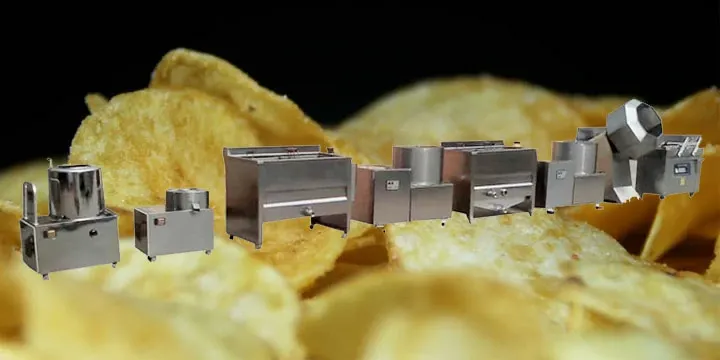

Small Scale Potato Chip Making Machine

A small scale potato chip making machine is designed for entrepreneurs and local businesses entering the snack market without heavy upfront investment.

Advantages of Small-Scale Machines

Compact structure and lower cost

Low power consumption

Easy operation and maintenance

Ideal for restaurants, cafés, food trucks, and local brands

Typical capacity ranges from 20–50 kg per hour, making it perfect for test production and regional sales.

Industrial Potato Chip Machine for High Capacity Production

An industrial potato chip machine is built for continuous operation and maximum efficiency. These systems are designed to run 24/7 and deliver stable output for large brands.

Key Benefits

Production capacity up to 1000 kg/h or more

Advanced automation and PLC control

Compatible with seasoning and packaging equipment

Durable design for long-term industrial use

Semi-Automatic Potato Chip Processing Equipment

A semi-automatic potato chip machine bridges the gap between manual processing and full automation. It is ideal for growing businesses that want more control without the cost of a fully automatic line.

Why Choose Semi-Automatic?

Lower initial investment

Manual control for feeding or seasoning

Easier operator training

Flexible for medium-scale production

Commercial Potato Chip Fryer Machine

Frying is the most critical stage in potato chip production. A commercial potato chip fryer machine directly impacts crispness, oil content, flavor, and shelf life.

Common Fryer Types

Batch Fryer: Ideal for small batches and new flavors

Continuous Fryer: Best for uninterrupted industrial production

Vacuum Fryer: Produces low-oil, healthier potato chips

Technical Specifications of Potato Chip Making Machine

| Component | Specification |

|---|---|

| Capacity | 100–1000 kg/h |

| Power Supply | 380V / 50Hz / 3 Phase |

| Total Power | 35–120 kW |

| Material | 304 / 316 food-grade stainless steel |

| Slice Thickness | 1–5 mm adjustable |

| Frying Temperature | 160–200°C |

| Heating Source | Electric / Gas / Diesel |

| Oil Filtration | Continuous filtration system |

| Water Consumption | 200–300 L/hour |

| Dimensions | Customizable |

| Labor Requirement | 2–5 operators |

Potato Chip Packaging Machine Integration

To maintain freshness and extend shelf life, a potato chip packaging machine is essential.

Packaging Features

Nitrogen flushing for freshness

Automatic sealing for hygiene

Compatible with pillow bags, gusseted bags, and stand-up pouches

Packaging systems can be seamlessly integrated with frying and seasoning units.

How to Choose the Right Potato Chip Making Equipment

1. Define Your Production Capacity

Small scale: 20–50 kg/h

Medium scale: 100–300 kg/h

Industrial scale: 500–1000+ kg/h

2. Decide the Automation Level

Manual: lowest cost, higher labor

Semi-automatic: balanced solution

Fully automatic: best consistency and efficiency

3. Plan Your Budget

Include:

Equipment cost

Utilities

Labor

Packaging

Return on investment

4. Focus on Food-Grade Materials

Always choose stainless steel construction for safety and durability.

Future Trends in Potato Chip Machinery

[Image Placeholder: Smart potato chip production line]

Emerging technologies are shaping the future of snack production:

IoT-based real-time monitoring

AI quality inspection systems

Energy-efficient heating solutions

These innovations improve efficiency, reduce waste, and support sustainable manufacturing.

Frequently Asked Questions

Q1: Can I start a potato chip business with a small machine?

Yes, small-scale machines are ideal for startups and local markets.

Q2: Which fryer is best for healthy potato chips?

Vacuum fryers use less oil and preserve nutrients.

Q3: How often does maintenance need to be done?

Regular cleaning, oil replacement, and inspection of moving parts are essential.

Q4: What is the most common packaging method?

Nitrogen-filled pillow bags are widely used for commercial potato chips.

Q5: How long does installation take?

Most potato chip production lines are installed within 5–10 days.

Conclusion

A potato chip making machine is a smart investment for businesses aiming to enter or expand in the snack food industry. From small-scale machines to fully automatic production lines, the right equipment ensures consistent quality, higher efficiency, and long-term profitability. By carefully evaluating capacity, automation level, and future scalability, manufacturers can build a reliable potato chip production system tailored to their market needs.

Looking for a supplier or want help choosing the best configuration? Contact us today and take the first step toward launching or expanding your potato chips business!