Frozen French fries have become one of the most popular ready-to-cook potato products worldwide. Served in fast-food restaurants, hotels, catering services, and households, the global demand for frozen fries continues to rise.

As consumption grows, investing in a frozen french fries production line has become a highly profitable opportunity for food manufacturers and entrepreneurs.

This guide explains everything you need to know — from market analysis and equipment selection to manufacturing process, packaging, and marketing — to help you successfully start a frozen french fries business.

1. Understanding the Frozen French Fries Market

1.1 Global Market Growth

The frozen french fries market is expanding rapidly due to:

Continuous growth of fast-food chains such as McDonald’s, KFC, and Burger King

Rising demand for frozen convenience food

Urban lifestyles favoring quick and easy meal preparation

Industry reports show the global frozen potato products market growing at over 5% annually, making frozen fries a long-term growth segment.

1.2 Target Customers

Identifying your target market helps determine production capacity and packaging format.

Main buyers include:

Fast-food restaurants and cafes

Frozen food distributors

Supermarkets and grocery chains

School and corporate canteens

Export markets in Asia, Africa, and the Middle East

2. Planning Your Frozen French Fries Business

2.1 Choosing the Right Production Scale

Before purchasing a frozen french fries machine, define your production goals:

Small-scale line: 100–300 kg/h (startups, local markets)

Medium-scale line: 500–1000 kg/h (regional distribution)

Fully automatic industrial line: 1500–3000 kg/h+ (export-oriented factories)

2.2 Factory Layout and Space Requirements

A standard frozen french fries production line requires:

500–2000 m² depending on capacity

Separate zones for washing, cutting, frying, freezing, and packaging

Stable electricity, clean water supply, gas (if applicable), and drainage

Proper factory planning ensures food safety compliance and smooth workflow.

2.3 Licenses and Certifications

To legally operate a frozen fries factory, you’ll need:

Business registration

Food processing license

Health and safety approval

Export license (for overseas sales)

3. Equipment for a Frozen French Fries Production Line

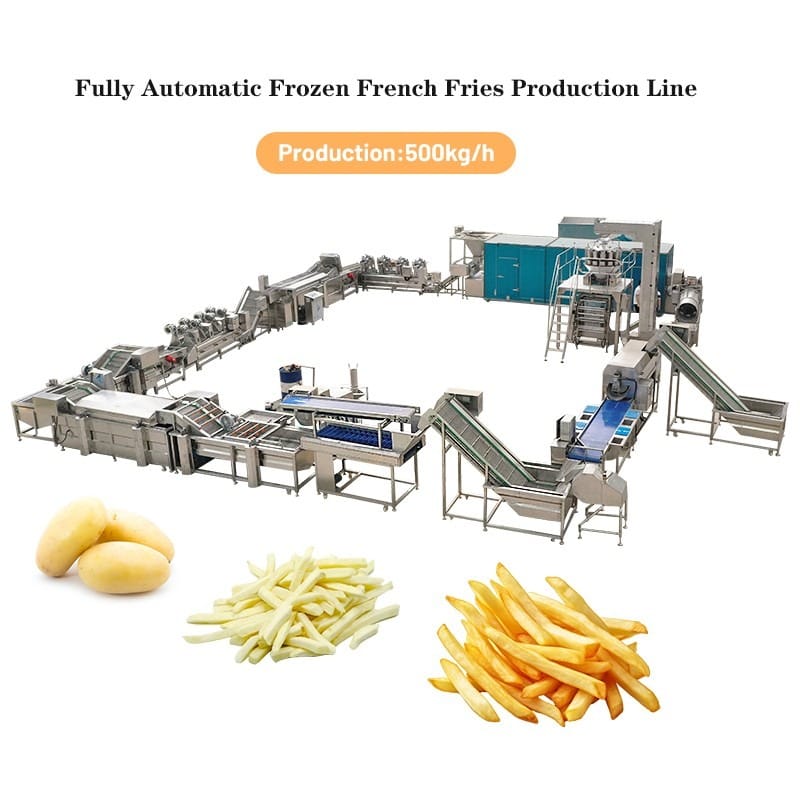

The core of your business is a fully automatic frozen french fries production line, consisting of multiple integrated machines.

3.1 Main Machines List

| Process | Machine | Function |

|---|---|---|

| Cleaning | Potato washing & peeling machine | Removes dirt and skin |

| Cutting | French fries cutting machine | Uniform fry size |

| Blanching | Blanching machine | Preserves color & texture |

| Dewatering | Dewatering machine | Removes surface water |

| Frying | Continuous fryer | Even pre-frying |

| De-oiling | De-oiling machine | Reduces oil content |

| Freezing | Blast freezer | Rapid freezing |

| Packing | Automatic packaging machine | Weighing & sealing |

3.2 Technical Parameters (Example)

| Model | Capacity | Power | Material |

|---|---|---|---|

| HANHUI-300 | 300 kg/h | 25 kW | SUS304 |

| HANHUI-500 | 500 kg/h | 45 kW | SUS304 |

| HANHUI-1000 | 1000 kg/h | 70 kW | SUS304 |

All frozen french fries machines can be customized according to capacity, voltage, and factory layout.

4. Frozen French Fries Manufacturing Process

4.1 Step-by-Step Production Process

A standard frozen fries processing flow includes:

Potato selection (high-starch varieties like Russet Burbank)

Washing and peeling

Cutting (8–12 mm thickness)

Blanching (color and texture control)

Air drying

Pre-frying at 170–180°C

De-oiling

Rapid freezing at -35°C to -40°C

Nitrogen-filled packaging

4.2 Quality Control Standards

To maintain consistent frozen fries quality:

Use SUS304 food-grade stainless steel equipment

Control blanching and frying temperature

Apply HACCP and ISO9001 systems

Perform daily equipment cleaning

5. Investment Cost and Profit Analysis

5.1 Estimated Investment (500 kg/h Line)

| Item | Estimated Cost |

|---|---|

| Frozen french fries production line | $35,000–$60,000 |

| Factory setup & utilities | $10,000–$20,000 |

| Labor & training | $5,000–$8,000 |

| Raw materials | $3,000–$5,000 |

| Marketing | $2,000–$5,000 |

| Total | $55,000–$95,000 |

5.2 Profit Potential

Average profit margins range from 20% to 35%.

A medium-scale frozen french fries factory can recover investment within 1–2 years, depending on market pricing and operating efficiency.

6. Frozen French Fries Packaging and Branding

6.1 Packaging Options

250 g retail packs

1 kg family packs

2.5 kg food-service packs

6.2 Branding Tips

Use clean, eye-catching designs

Highlight “Crispy Texture” and “Premium Potatoes”

Add QR codes for traceability

Offer eco-friendly packaging options

7. Marketing and Distribution Strategy

7.1 Online Marketing

Build an SEO-optimized website

Promote frozen french fries products on B2B platforms

Run targeted ads for distributors and restaurants

7.2 Offline & Export Channels

Partner with supermarkets and foodservice chains

Attend food exhibitions

Focus on export markets such as the Middle East, Africa, and Southeast Asia

8. Choosing a Frozen French Fries Machine Supplier

Why Choose HANHUI Food Machine

HANHUI Food Machine is a professional frozen french fries production line manufacturer, offering:

Automatic and semi-automatic lines (100–3000 kg/h)

SUS304 stainless steel construction

Customized factory layout design

Installation, training, and lifetime technical support

9. Common Problems and Solutions

| Problem | Solution |

|---|---|

| Uneven fry color | Control blanching & oil temperature |

| High oil usage | Use de-oiling & filtration systems |

| Poor crispiness | Optimize pre-frying time |

| Short shelf life | Nitrogen-filled packaging |

10. Final Thoughts: Start Your Frozen French Fries Business

Starting a frozen french fries business is a smart investment when supported by the right production line, reliable equipment, and market strategy. With growing global demand and scalable production, frozen fries offer long-term profitability.

HANHUI Food Machine provides one-stop frozen french fries production solutions, from factory design to equipment installation.

👉 Contact us today to receive a customized frozen french fries production line quotation.