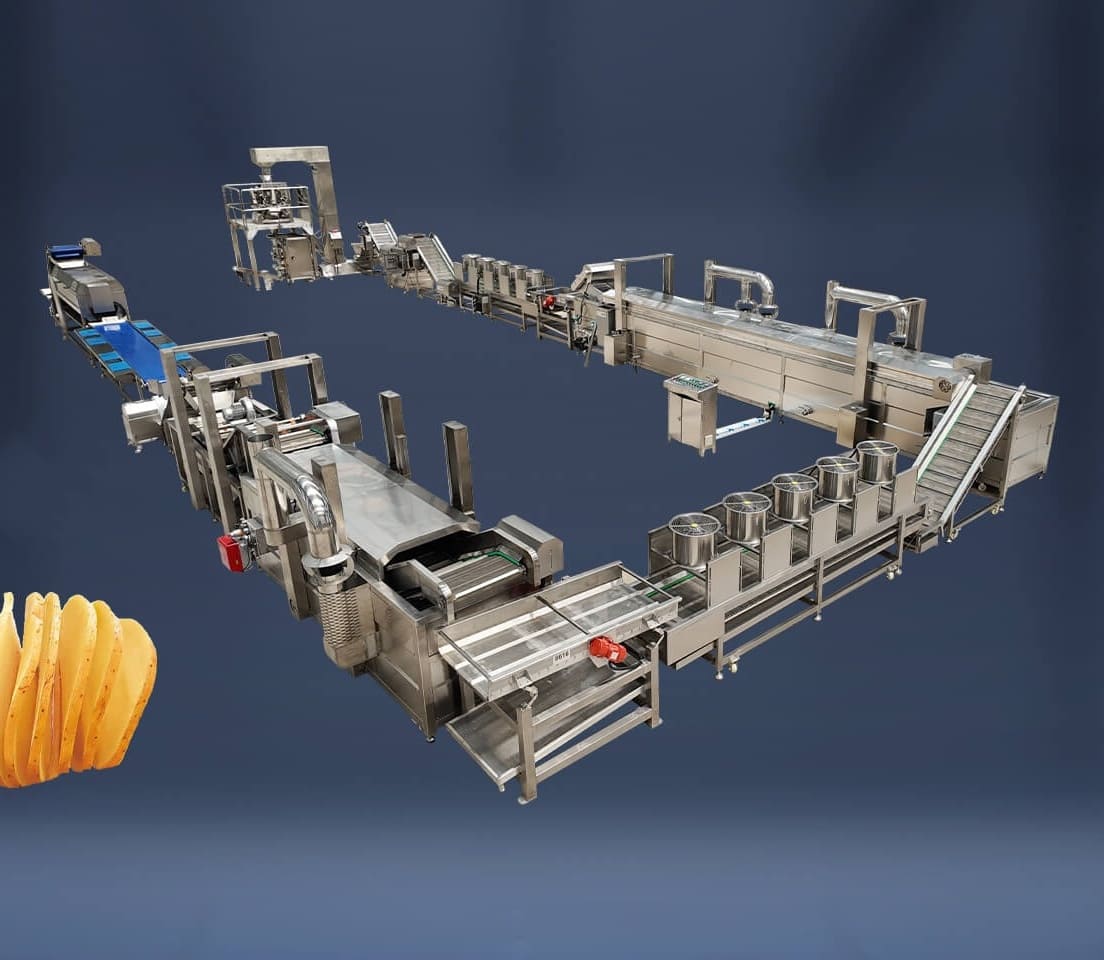

A fully automatic potato chips production line is an industrial food processing solution designed for large-scale potato chips manufacturing. It integrates washing, peeling, slicing, frying, seasoning, cooling, and packaging into one continuous and automated potato chips processing line.

As a professional potato chips production line manufacturer, HANHUI Food Machine provides turnkey solutions that help snack food factories improve production efficiency, reduce labor costs, and achieve consistent product quality.

Automatic Potato Chips Production Line Overview

This automatic potato chips making machine line is widely used by:

Commercial potato chips manufacturers

Snack food processing factories

Industrial potato processing plants

Investors entering the potato chips production business

With advanced automation and PLC control, the line ensures uniform slicing, stable frying temperature, and consistent seasoning, making it ideal for export-oriented potato chips factories.

Working Process of the Potato Chips Processing Line

The fully automatic potato chips processing line consists of the following key machines:

1. Potato Washing and Peeling Machine

Fresh potatoes are cleaned and peeled using a rotary brush system with water circulation.

Capacity: 300–2000 kg/h

Material: SUS304 food-grade stainless steel

Application: Industrial potato washing and peeling

2. Automatic Potato Slicing Machine

The washed potatoes are sliced evenly to ensure uniform frying.

Slice thickness: 0.8–2.0 mm adjustable

Output: 300–800 kg/h

Advantage: Low damage rate, smooth cutting surface

Uniform slicing directly affects potato chips quality and frying efficiency.

3. Rinsing and Blanching Machine

The potato slices are rinsed to remove excess starch and blanched to improve texture.

Blanching temperature: 80–95°C

Time: 1–3 minutes

Function: Prevents browning and improves crispiness

This step is essential in any industrial potato chips production line.

4. Dewatering Machine

Excess moisture is removed before frying to reduce oil absorption.

High-speed centrifugal dewatering

Reduces oil consumption

Improves final potato chips texture

5. Continuous Potato Chips Frying Machine

The continuous frying machine is the core equipment of the potato chips production line.

Frying temperature: 160–180°C

Heating: Electric / Gas / Diesel

Oil circulation and filtration system

Ensures even frying and stable color for commercial potato chips production.

6. Deoiling Machine

The fried potato chips are deoiled to remove surface oil.

Centrifugal deoiling system

Improves shelf life and taste

7. Potato Chips Seasoning Machine

Flavor powders are evenly coated using a rotary seasoning drum.

Automatic seasoning machine for potato chips

Adjustable speed

Suitable for multiple flavors

8. Cooling and Potato Chips Packaging Machine

The cooled potato chips are packed automatically.

Functions: Weighing, filling, sealing

Packaging type: Pillow bag or gusset bag

Optional nitrogen flushing

Advantages of Fully Automatic Potato Chips Production Line

✔ High Automation

PLC-controlled potato chips processing line with touch screen operation.

✔ Food-Grade Materials

All machines use SUS304 stainless steel, meeting international food safety standards.

✔ Energy-Saving Design

Efficient oil filtration and heat recovery reduce operating costs.

✔ Stable Product Quality

Consistent thickness, frying temperature, and seasoning ensure uniform potato chips quality.

✔ Custom Potato Chips Factory Solutions

From small-scale potato chips production lines to industrial systems.

Applications of Potato Chips Making Machine

This automatic potato chips production line can produce:

Fried potato chips

Potato crisps

Sweet potato chips

Banana and cassava chips

Used in:

Snack food factories

Frozen food processing plants

Food export enterprises

How to Start a Potato Chips Manufacturing Business

Choose the right potato chips production capacity

Prepare factory space, electricity, gas, and water

Select a reliable potato chips production line manufacturer

Install and commission the machines

Train operators and establish quality control

HANHUI Food Machine provides complete potato chips factory solutions.

Why Choose HANHUI Food Machine?

HANHUI Food Machine is a trusted fully automatic potato chips production line manufacturer with global service experience.

15+ years manufacturing experience

CE & ISO certified potato chips machines

Installation and training worldwide

Exported to over 60 countries

Optional Equipment for Potato Chips Factory Expansion

Automatic potato sorting machine

Oil filtration system

Nitrogen flushing packaging machine

Continuous conveyor system

Conclusion

A fully automatic potato chips production line is the best solution for manufacturers seeking high efficiency, stable quality, and scalable snack food production. As an experienced potato chips production line manufacturer, HANHUI Food Machine delivers reliable, customizable, and energy-efficient potato chips making machines for global markets.

If you’re looking to start or upgrade your potato chips production line, contact HANHUI Food Machine today — your reliable manufacturer of automatic potato chips making machines.