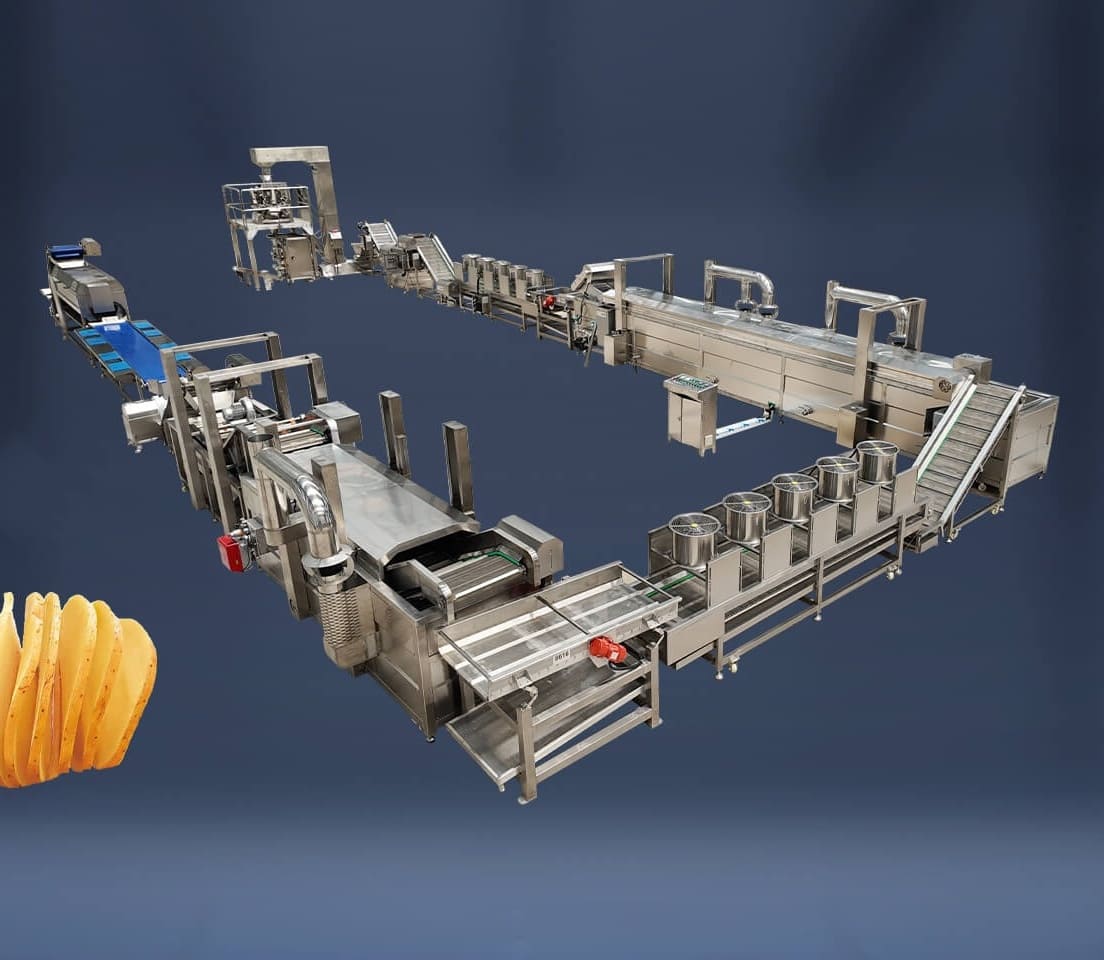

Potato chip production involves multiple steps and requires reliable, high-performance equipment. Efficient machinery improves product quality, reduces downtime, and increases profitability. Hanhui provides easy-to-use, durable equipment for every stage of potato chip processing.

1. Why Upgrading Potato Chip Equipment Matters

Potato chip production is a complex process requiring efficient, reliable, and purpose-built machines. Using outdated equipment leads to:

Reduced yield and quality

Higher labor costs

Production bottlenecks

Lost contracts and brand reputation

Upgrading to Hanhui potato processing equipment improves efficiency, reduces waste, and ensures consistent product quality.

Keywords: potato chip production equipment, Hanhui potato processing, potato chip line efficiency

2. Receiving – The Start of Your Production Line

Efficient receiving is critical to avoid bruising, contamination, and downtime. Key aspects:

Product Handling

Bulk bins with ventilation

Oversize flume systems

Automated controls

Dumper Engineering

Avoid free-fall bruising

Consistent flow to prevent bottlenecks

Destoning

Removes rocks and debris

Improves product quality

Reduces equipment downtime

Automation & Maintenance

Automated receiving improves flow

Durable construction reduces breakdowns

Maintenance-friendly design saves labor costs

Potato Chip Receiving Equipment

3. Peeling – Increase Yield and Quality

High-quality peeling machines maximize usable yield and improve chip consistency.

Common Peeler Shortcomings

Frequent maintenance and part replacement

Capacity constraints

Reduced yield and quality

Water Conservation Solutions

Auger separates starch and solids from water

Recycles up to 90% of process water

Reduces wastewater treatment costs

Manual vs Automated Operations

Manual peeling is labor-intensive and inconsistent

Semi-automated lines still require oversight

Fully automated continuous operation maximizes throughput

4. Supporting Equipment – Hidden Efficiency Costs

Supporting infrastructure can either optimize or bottleneck production.

Critical Supporting Equipment

Platforms and catwalks

Transfer and inspection conveyors

Potential Issues

Outdated infrastructure limits production speed

Maintenance challenges increase labor needs

Manual handling slows down throughput

Lack of inspection systems reduces quality control

Upgrading supporting equipment enhances safety, reduces labor, and increases production capacity.

5. Hanhui Solutions – Upgrade Your Potato Chip Line

Hanhui offers durable, high-quality, easy-to-use equipment designed for 24/7 operation.

Key Benefits

| Feature | Benefit |

|---|---|

| Maintenance & Sanitation | Tool-free part changeouts, Clean-in-Place (CIP) systems |

| Durable Design | Long lifespan, high-demand performance |

| Reduced Labor | Automation reduces need for skilled staff |

| Water Conservation | Closed-loop system recycles water, reduces costs |

| Seamless Integration | Works with new or existing lines |

| Consistent Quality | Maximized usable yields and product consistency |

Highlighted Equipment

2920 Peeler/Scrubber/Washer: Continuous operation with minimal downtime

Waste Separating Auger: Filters peel waste, reduces water consumption, collects peels for resale

Hanhui Potato Chip Processing Equipment

6. Profit-Boosting Advantages of Hanhui Equipment

Increased production capacity

Reduced downtime and labor costs

Improved product quality

Long-term operational reliability

Sustainable water and energy usage

7. FAQ – Potato Chip Processing Equipment

How does Hanhui improve potato chip yields?

Advanced peeling, destoning, and water reclamation systems maximize usable potatoes and reduce waste.

Can Hanhui equipment integrate into existing lines?

Yes, all Hanhui machines are designed for seamless integration.

How does water reclamation work?

Augers filter solids from peeler water, recycle it into the system, reducing freshwater consumption by up to 90%.

Is the equipment labor-saving?

Yes, automated systems reduce manual oversight, training requirements, and labor costs.

Conclusion

Upgrading your potato chip production line with Hanhui equipment optimizes efficiency, reduces costs, and ensures consistent high-quality products. From receiving and peeling to supporting infrastructure, Hanhui provides a full suite of solutions to increase profitability and sustainability.

Call to Action: Contact Hanhui Today to Upgrade Your Potato Chip Line