Potato chips are one of the most popular snack foods in the world. As a global food crop, potatoes rank second in human consumption after rice. But how did simple potatoes evolve into the crispy, mass-produced potato chips we enjoy today?

This article explores the origin of potato chips, their industrial development, and the modern technology used in potato chips production.

The Origin of Potato Chips

There are many stories about the invention of potato chips, but the most widely accepted one dates back to 1853 in Saratoga Springs, New York.

George Crum, a local chef working at Moon’s Lake House, was serving traditional thick-cut fried potatoes. One demanding customer complained that the potatoes were too thick and asked for thinner slices. After several attempts, an annoyed Crum sliced the potatoes extremely thin and fried them until crisp, assuming the customer would dislike them.

To his surprise, the customer loved the result. These thin, crispy slices quickly became popular and were soon known as “Saratoga Chips.” What started as an accident soon turned into a culinary sensation.

From Handcrafted Food to Industrial Snack

Early Production Challenges

In the early 19th century, potato chips were made entirely by hand. Potatoes were peeled and sliced manually, which severely limited production capacity and consistency.

The breakthrough came in the 1920s with the invention of the mechanical potato peeler, which made large-scale production possible and transformed potato chips from a restaurant specialty into a commercial snack.

Development of Potato Peeling Technology

The invention of the potato peeler has long been debated. Two commonly mentioned figures are Herman Lay and Alfred Neweczeral. Among them, Alfred Neweczeral is widely credited with inventing the famous Rex Y-type potato peeler in 1947.

This peeler became so iconic that it was featured on a Swiss postage stamp in 2004.

Common Types of Potato Peelers

Today, several types of potato peelers are widely used:

Straight peelers: Knife-like design with a blade parallel to the handle

Y-type peelers: Safety-razor style with a perpendicular blade

Mechanical peelers: Crank-operated or motorized machines for large volumes

Some advanced mechanical peelers can peel, core, and slice potatoes in a single operation.

Industrial Potato Chips Production Process

In modern potato chips factories, the process is highly automated and standardized.

Typical Industrial Workflow:

Washing – Potatoes are cleaned using water and soft brushes

Peeling – Mechanical peelers remove skins using rollers with rubber studs

Slicing – Potatoes are cut into uniform thin slices

Frying – Slices are fried at controlled temperatures

Seasoning – Flavorings are evenly applied

Packaging – Chips are sealed to maintain freshness

Similar tumbling peeling systems are also used for vegetables like tomatoes and carrots, ensuring efficiency and minimal waste.

Growth of the Potato Chips Industry

After George Crum opened his own restaurant in 1860, potato chips spread rapidly across the United States. Soon, restaurants nationwide began serving them.

Entry into Grocery Stores

William Tappendon of Cleveland, Ohio, is credited with bringing potato chips into grocery stores. In the 1890s, he converted his barn into what is considered the world’s first potato chips factory, supplying local retailers.

By the early 1900s, large factories were built to meet growing demand. The 1920s marked the rise of major brands such as:

Wise Potato Chips

Lay’s Potato Chips

Utz Hanover Home Brand

Packaging Innovations That Changed Everything

Early potato chips were packaged in barrels or tins, which caused chips at the bottom to become stale and crushed.

In 1926, Laura Scudder revolutionized the industry by introducing wax paper bags. This innovation reduced breakage and kept chips fresh longer. Later, the invention of cellophane packaging allowed potato chips to become a true mass-market product.

Today, potato chips are packed in nitrogen-filled plastic bags, which:

Prevent oxidation

Extend shelf life

Protect chips from crushing

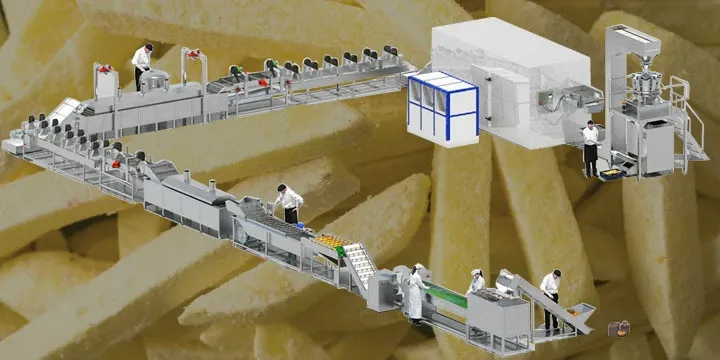

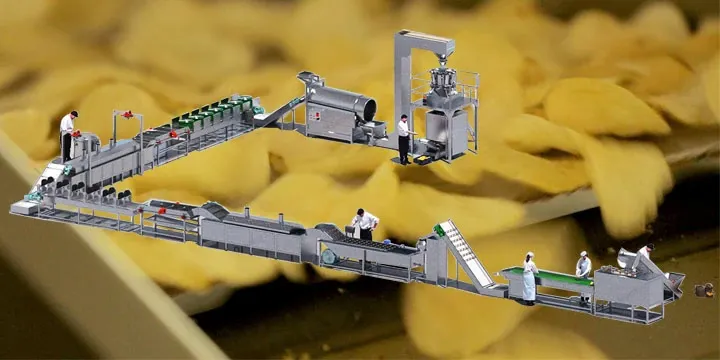

Modern Technology for Potato Chips Production

Modern potato processing technology has made large-scale production highly efficient.

An automatic potato chips production line can handle the entire process—from washing and peeling to frying and packaging—with minimal manual labor. This ensures:

Consistent product quality

Higher output capacity

Reduced labor costs

Reliable Potato Processing Machinery Supplier

Amisy Machinery specializes in advanced potato processing equipment for both potato chips and French fries production. We are committed to providing:

High-quality machines

Competitive pricing

Reliable after-sales service

Our solutions are designed to support food manufacturers at every production scale.

Conclusion

From a simple kitchen accident in 1853 to today’s fully automated factories, potato chips have undergone remarkable technological evolution. Modern industrial production lines and advanced packaging methods have transformed potato chips into one of the world’s most popular and reliable snack foods.