Starting a frozen fries factory in Europe requires more than just buying equipment — it involves compliance, production planning, and choosing the right processing capacity.

Below is a practical buyer guide answering the most common questions European investors search before purchasing a frozen French fries production line.

How Much Does a Frozen French Fries Line Cost?

Short Answer:

Small line: $30,000 – $80,000

Medium line: $80,000 – $200,000

Industrial line: $200,000 – $500,000+

Why Prices Vary

The price mainly depends on:

Production capacity

Automation level

Freezing technology (IQF vs tunnel freezer)

Oil filtration system

CE safety configuration

Stainless steel grade (SUS304 vs SUS316)

Factories targeting supermarkets usually need higher automation and freezing performance than foodservice suppliers.

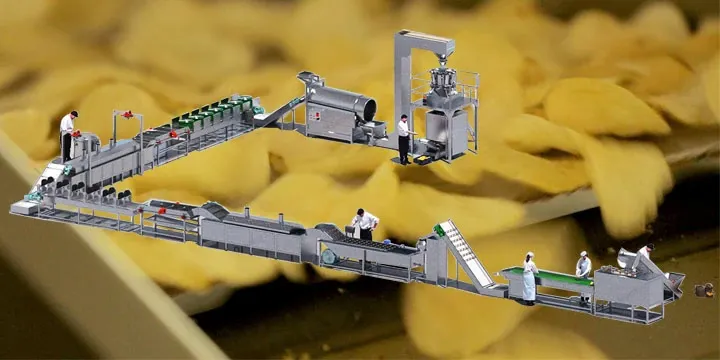

What Machines Are Needed for Frozen French Fries Production?

A frozen fries factory uses a continuous processing system.

Standard Processing Line

Potato washing & peeling

Cutting machine

Blanching machine

Dewatering & drying

Continuous fryer (optional)

IQF freezer

Automatic packaging machine

The configuration can be adjusted for straight-cut, crinkle-cut, or steak fries.

Do Frozen Fries Machines Need CE Certification in Europe?

Yes — CE compliance is mandatory.

Without CE documentation, equipment cannot legally operate in EU food factories.

Required Standards

CE certification

HACCP hygienic design

Food-grade stainless steel

Emergency safety systems

EU electrical compatibility (380–415V / 50Hz)

Buyers should always request the Declaration of Conformity before purchase.

What Capacity Should a New Factory Choose?

| Factory Stage | Recommended Capacity |

|---|---|

| Startup / Pilot | 200–500 kg/h |

| Local Brand | 500–1000 kg/h |

| Export Supplier | 1000–3000 kg/h |

Choosing oversized equipment often increases energy cost without improving profitability.

How Does the Frozen French Fries Production Process Work?

1️⃣ Cleaning & peeling remove dirt and skin

2️⃣ Cutting ensures uniform size

3️⃣ Blanching stabilizes color

4️⃣ Drying improves frying efficiency

5️⃣ Frying creates texture

6️⃣ Freezing preserves taste

7️⃣ Packaging prepares retail distribution

Each step directly affects product quality and shelf life.

Is Importing Equipment Cheaper Than Buying in Europe?

Usually yes.

Many European processors import equipment because:

Lower investment cost

Customizable layouts

Faster delivery

However, buyers must confirm CE compliance and technical support availability.

What Should You Check Before Choosing a Supplier?

EU export experience

Real project references

CE documentation

Installation support

Spare parts availability

The supplier should provide long-term technical cooperation, not just sell machinery.

What Are the Future Trends in Frozen Fries Processing?

European factories are upgrading toward:

Energy-saving fryers

Low oil absorption technology

Smart PLC control

Sustainable production systems

New equipment is designed to reduce labor and operating cost.

Final Advice

Purchasing a frozen French fries processing line is not just a machine investment — it is a production strategy decision.

Choosing the correct capacity, ensuring EU compliance, and working with an experienced manufacturer will determine whether the factory operates profitably for the next 10+ years.