The demand for potato chips remains stable worldwide, making the snack industry attractive for entrepreneurs. Many investors want to enter the market but the first question is always:

How much does it cost to start a potato chip business?

This guide explains the main cost components for launching a small-scale potato chip production project, helping you plan a realistic startup budget.

1. Facility Costs

Small chip production does not require a large factory.

Recommended space: 100–200 m²

This area is sufficient for:

Production area

Raw material storage

Finished product storage

Cost Characteristics

No complex infrastructure required

Rental expenses remain manageable

Suitable for startup businesses

Small workshops significantly reduce initial investment risk.

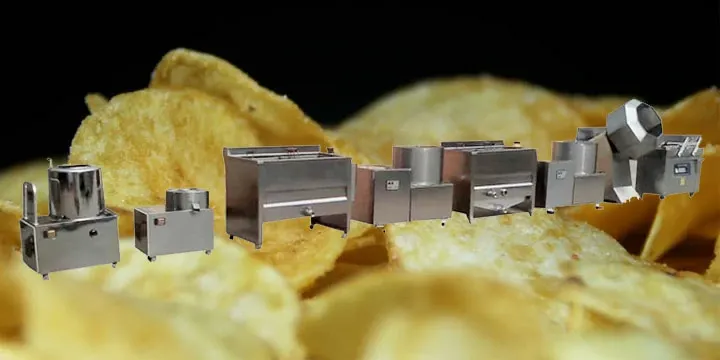

2. Equipment Costs (Main Investment)

Equipment is the largest expense in a potato chip business.

For a capacity of 100–200 kg per hour, a semi-automatic potato chip production line offers the best balance between cost and performance.

Main Machines Included

Washing & peeling machine

Slicing machine

Blanching machine

Frying machine

De-oiling machine

Seasoning machine

Packaging machine

Equipment Budget

Estimated investment: $20,000 – $50,000

Advantages

Low entry barrier

Short payback period

Easy operation

Low maintenance cost

Upgradeable to full automation later

For first-time investors, modular equipment reduces financial risk.

3. Labor Costs

Small production lines require minimal staffing.

Recommended workforce: 3–4 workers

| Task | Personnel |

|---|---|

| Washing & slicing | 1–2 people |

| Frying & seasoning | 1 person |

| Packaging & inspection | 1 person |

Automation keeps labor costs low while maintaining consistent output.

4. Other Operating Costs

Besides core expenses, you should also budget for ongoing operating costs:

Raw materials (potatoes, oil, seasoning)

Utilities (water, electricity, gas)

Packaging materials

These costs vary by region but remain manageable for small-scale operations.

Is a Small Potato Chip Business Profitable?

Because potato chips are a high-demand snack, small factories can scale gradually:

Start with semi-automatic production

Build local distribution

Expand capacity

Upgrade to full automation

The moderate startup cost combined with strong consumer demand creates solid profit potential.

Conclusion

Starting a small potato chip business does not require a massive investment. With a budget mainly allocated to equipment, a small workshop, and a small team, entrepreneurs can enter the snack manufacturing industry with relatively low risk.

Typical startup budget structure:

Facility: low cost

Equipment: $20,000–$50,000 (primary investment)

Labor: 3–4 workers

Operating costs: variable but controllable

A carefully planned small production line allows gradual expansion and sustainable growth in the snack market.