Potato chips are undoubtedly one of the most popular snacks in the world. From classic flavors like original, barbecue, sour cream & onion, and salt & vinegar, to creative tastes such as garlic prawns or seafood-inspired seasonings, potato chips continue to win consumers’ hearts globally.

Behind every crispy chip is a production process shaped by decades of technological innovation. But what did potato chips production look like before modern automated lines existed? Let’s explore the evolution of potato chips manufacturing—from manual processing to today’s fully automatic production lines.

1. Manual Potato Chips Production Before the 1920s

Potato chips originated in 1853 at a hotel in the United States. According to popular history, chef George Crum created the first potato chips after a customer complained that fried potatoes were sliced too thick. Crum responded by slicing the potatoes extremely thin, frying them until crispy, and adding salt. Unexpectedly, the dish became an instant hit.

During this early period, potato chips were mainly produced by hand. Potatoes were peeled, sliced, fried, and seasoned manually. Production was limited to small restaurants and local grocery stores, and output remained low due to the lack of machinery.

2. Semi-Automatic Potato Chips Production (1920s–1980s)

As potato chips grew in popularity, the industry began adopting mechanical innovations to improve efficiency and consistency.

In 1920, Herman Lay introduced a mechanical potato peeler, greatly improving peeling speed and labor efficiency. This milestone marked the transition toward semi-automatic potato chips production.

Another major breakthrough came in 1926, when entrepreneur Laura Scudder pioneered sealed packaging using waxed paper bags. This innovation helped protect chips from moisture and breakage during transportation. Later, cellophane and glassine bags further improved packaging quality.

In the 1950s, Joe Murphy, founder of the Irish crisp brand Tayto, developed modern potato chips seasoning technology, allowing manufacturers to add various flavors consistently and at scale.

These developments laid the foundation for mass production of potato chips and expanded their availability worldwide.

3. Fully Automatic Potato Chips Production Since the Late 1980s

From the late 1980s onward, potato chips manufacturing entered the era of full automation.

Key technological advancements include:

Microprocessor-controlled weighing systems (1980s) for precise portioning

Optical sorting technology (1990s) to remove defective potatoes and chips

Nitrogen-filled packaging (introduced in 1995) to preserve freshness and extend shelf life

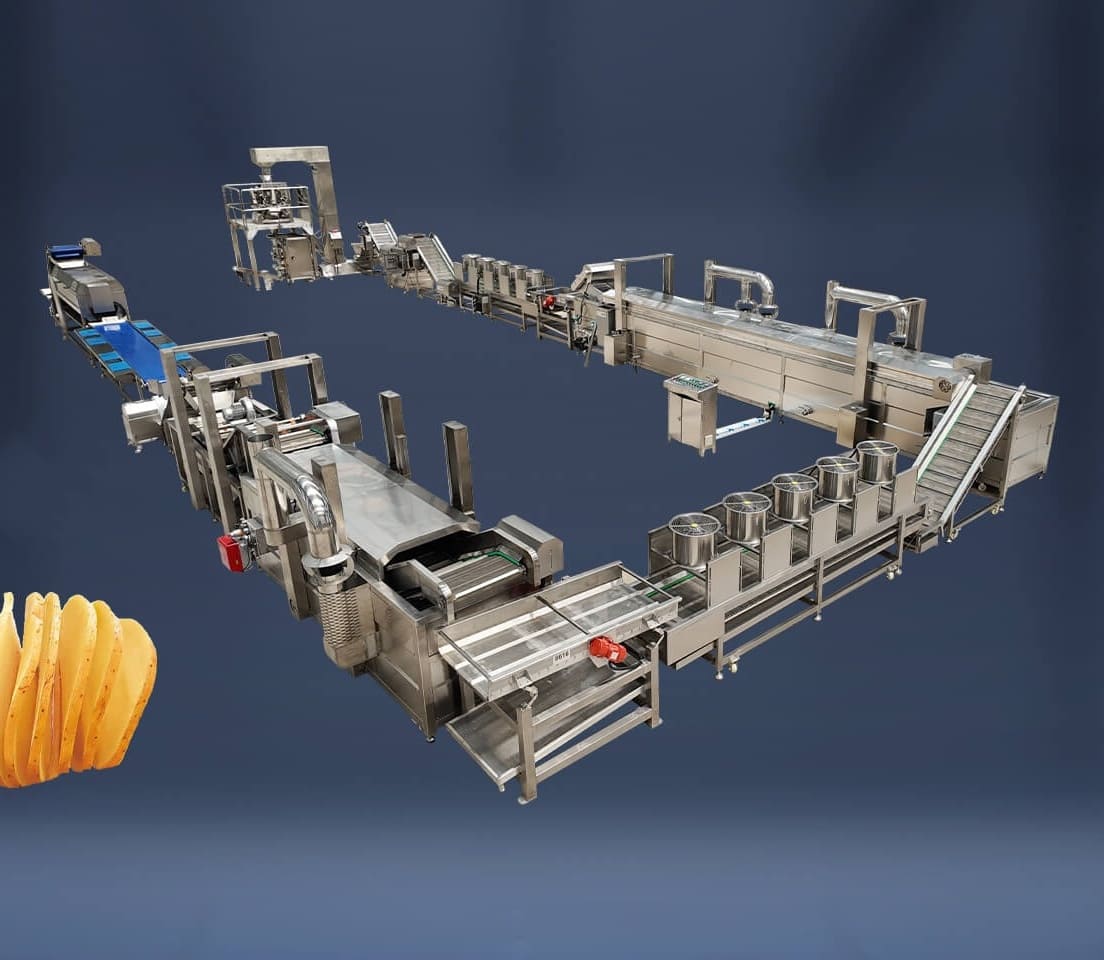

Modern potato chips production lines integrate washing, peeling, slicing, blanching, frying, de-oiling, seasoning, and packaging into a continuous, automated process. Packaging materials now include PP, PE, PVC, HDPE, PS, ensuring safety, durability, and extended freshness.

These innovations enable manufacturers to meet large-scale market demand while maintaining stable quality.

Potato Chips Industry Outlook and Business Opportunity

Today, potato chips technology is highly mature, and equipment performance continues to improve. Potato chips show no signs of declining popularity.

In 2023, global potato chips sales reached approximately USD 30 billion, making the potato chips industry a strong and profitable business opportunity. Whether for small startups or large-scale factories, investing in a modern potato chips production line offers long-term potential.

We supply small, medium, and large-capacity potato chips production lines, as well as individual potato chips machines, with high quality, stable performance, and competitive pricing to meet different production needs.

Article Summary

This article outlines the complete evolution of potato chips production—from early manual methods to today’s fully automatic production lines. With mature technology, advanced equipment, and strong global demand, the potato chips industry remains a highly attractive investment for food manufacturers worldwide.