Introduction to Potato Chips & Banana Chips

Potato chips and banana chips are among the most popular snack foods worldwide. Loved by consumers of all age groups and income levels, these crispy, crunchy snacks have become a staple in the global processed food industry.

Both potato chips and banana chips are made from sliced raw materials that are deep-fried or dried, creating high value-added snack products that are hard to resist. While fresh potatoes and bananas are healthier, their short shelf life makes processing essential for large-scale distribution and long-term storage.

Although both snacks offer some nutritional value, they should always be consumed in moderation due to their high fat content.

Potato Chips vs Banana Chips: Nutritional Comparison (per 100g)

| Nutrient | Potato Chips | Banana Chips |

|---|---|---|

| Calories | 547 kcal | 519 kcal |

| Carbohydrates | 49.74 g | 58.40 g |

| Fat | 37.47 g | 33.60 g |

| Protein | 6.56 g | 2.30 g |

Source: Instant Food Comparison

Key insight:

Potato chips contain slightly less carbohydrates, while banana chips provide higher natural sugar content and certain micronutrients derived from bananas.

Global Market Potential

Potato Chips Market

The global potato chips market generated approximately USD 25.7 billion in 2012, growing at a CAGR of 4.8% between 2008 and 2012. During the same period, consumption volume increased at a CAGR of 3.3%, reaching 3.05 million kilograms in 2012.

The market was projected to reach USD 32.5 billion by 2017, supported by increasing urbanization, demand for convenience foods, and product flavor innovation.

Banana Chips Market

Compared to the potato chips industry, the banana chips market shows strong growth potential with less intense competition. As consumer interest in fruit-based snacks rises, banana chips are gaining popularity, especially in health-conscious and emerging markets.

To remain competitive, manufacturers must focus on:

Improving production efficiency

Enhancing packaging quality

Strengthening branding for premium banana chips

Manufacturing Process of Potato Chips & Banana Chips

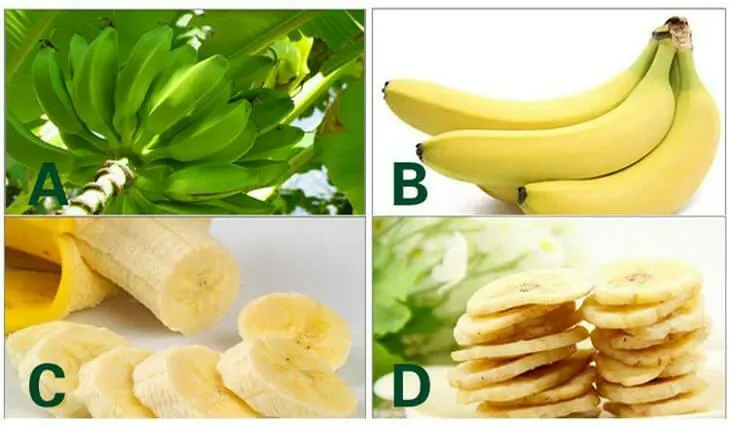

1. Raw Material Preparation

Potatoes and bananas are thoroughly washed, peeled, and sliced using a potato slicing machine or banana slicing machine.

Banana slices are soaked in brine water to prevent oxidation. Potato slices are soaked in water or water containing 0.5% potassium metabisulphite for the same purpose.

2. Color & Quality Enhancement

In banana chip processing, turmeric or ginger powder may be added to enhance color and visual appeal.

3. Blanching

Potato slices are blanched for 3–5 minutes at 70–90°C. Banana slices require less blanching time. This step improves texture and reduces enzymatic browning.

4. De-watering

Excess water is removed using a centrifugal de-watering machine, preparing the slices for frying.

5. Frying

Banana chips: Typically fried in coconut oil

Potato chips: Commonly fried in sunflower oil

Controlled frying ensures consistent texture and flavor.

6. De-oiling, Seasoning & Packaging

After frying, excess oil is removed, and the chips are seasoned. Finished products are packed in sealed polyethylene bags to prevent spoilage. Attractive packaging is strongly recommended over bulk sales for better market acceptance.

Processing Equipment for Chips Production

Modern snack manufacturing relies on automated and semi-automated equipment. Potato chips production lines and banana chips production lines typically include:

Washing & peeling machines

Slicing machines

Blanchers

De-watering systems

Fryers

De-oiling machines

Seasoning & packaging machines

Advanced production lines help manufacturers achieve higher efficiency, consistent quality, and scalable output.

Conclusion

Potato chips and banana chips are both highly profitable snack products with strong global demand. While potato chips dominate the market in scale, banana chips offer growing opportunities with less competition. Choosing the right raw materials, efficient manufacturing processes, and modern processing equipment is essential for producing high-quality chips and staying competitive in the snack food industry.