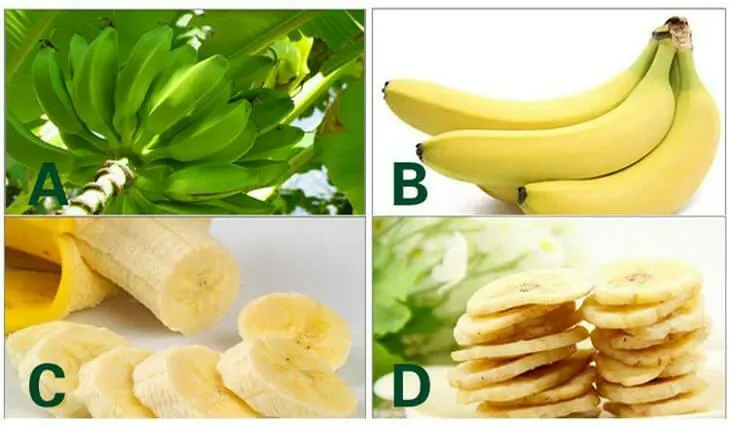

High-efficiency banana / plantain chips production line with capacities from 100 to 300 kg/h, customizable for different production needs.

Fully automatic operation ensures stable quality, low labor cost, and compliance with food hygiene standards.

Automatic Plantain Chips Production Line – Working Process

A complete automatic banana / plantain chips production line includes the following steps:

Peeling (manual or automatic)

→ Slicing

→ Frying

→ De-Oiling

→ Seasoning

→ Damaged Chips Sorting

→ Packing

1. Banana Peeling Machine (Optional)

The automatic green banana peeling machine reduces labor cost and improves working efficiency.

It is suitable for plantains and green bananas, with no strict size requirements.

Available Capacity: 150 kg/h · 300 kg/h

2. Banana Slicing Machine

Designed for uniform banana slicing with adjustable thickness to meet different product requirements.

Slice thickness can be freely adjusted from 1–5 mm.

The feed inlet diameter is customizable from 25 to 150 mm, making the machine suitable for bananas of various sizes.

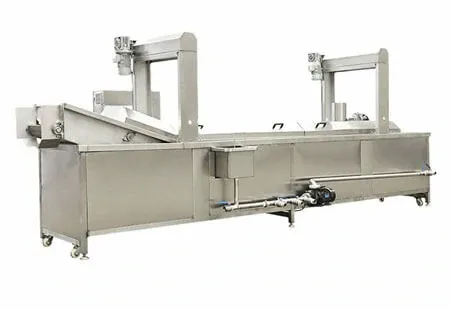

3. Plantain Chips Frying Machine

The frying machine adopts oil–water separation technology, allowing food residues to settle and be easily removed for cleaner operation.

It supports continuous frying using pure edible oil at a working temperature of 180 °C.

Designed for energy-saving and labor-efficient production, the machine ensures uniform color, texture, and product quality.

4. Vibrating Plantain Chips De-Oiling Machine

This machine uses vibration technology to remove excess oil from fried plantain or banana chips.

The built-in vibrating feeding system enables automatic and uniform conveying, reducing manual handling.

By lowering oil content, it improves taste and texture while ensuring smooth transfer to the next processing stage.

5. Banana Chips Cooling & De-Oiling Machine

This machine uses an air-blowing system to quickly cool fried banana chips while removing excess surface oil.

It helps improve product crispness and quality, preparing the chips for the next processing stage.

6. Seasoning Machine

This machine evenly coats fried banana or plantain chips with seasoning, enhancing their flavor and taste.

Designed for consistent and uniform seasoning, it ensures each chip meets high-quality standards.

7. Automatic Chips Packing Machine

This machine automatically packs plantain or banana chips into bags, completing all processes including feeding, counting, filling, bag making, and date printing.

It delivers efficient, consistent, and hygienic packaging for finished products.

In addition to the main machines, the banana/plantain chips production line includes auxiliary equipment such as material elevators, conveyor belts, and other connecting devices to ensure smooth and continuous production.

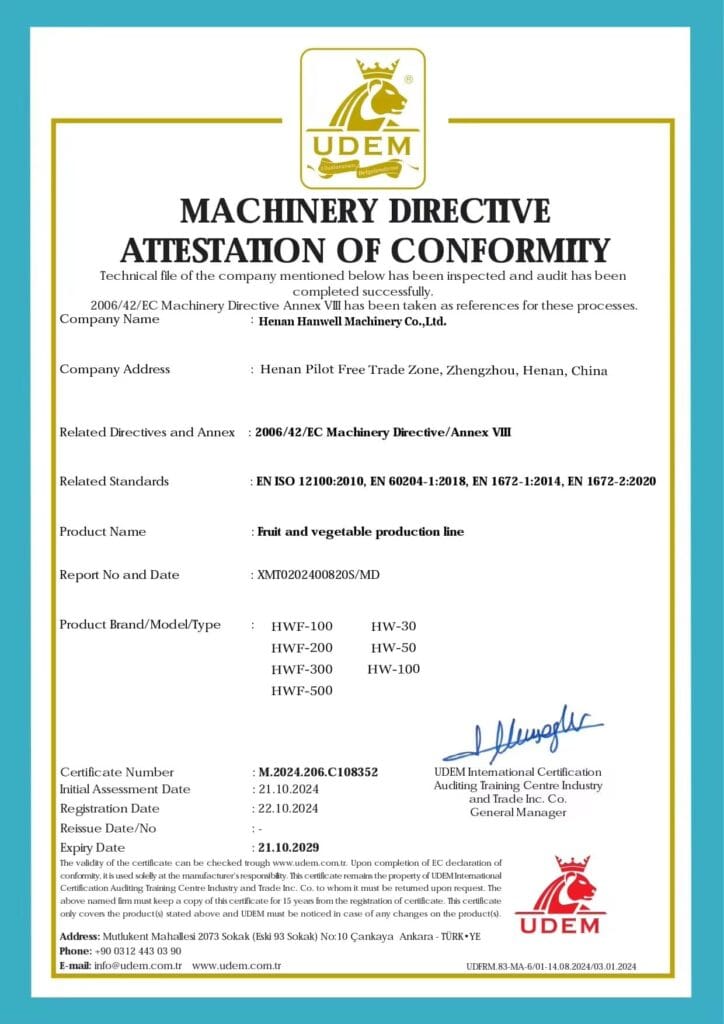

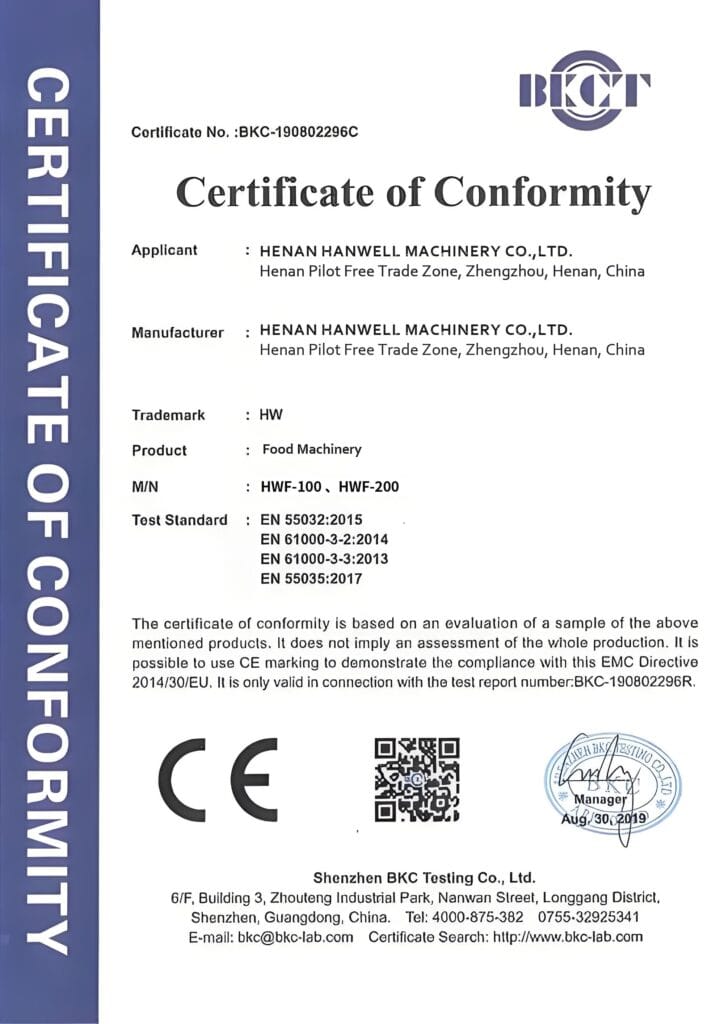

Global Advanced Technology – Designed with internationally recognized standards.

Excellent Product Quality – Consistent, crispy, and tasty chips.

Efficient Oil Management – Reduces oil content and improves product quality.

Compact Structure & Attractive Design – Space-saving and visually appealing.

Low Energy Consumption & Easy Operation – Reduces costs and labor.

Thorough Quality Testing – Each line inspected before shipping.

Trusted Worldwide – Widely used by customers globally.

Comprehensive After-Sales Service – Ensures smooth operation and support.

Fast, customized solutions for your food production line. Talk to our experienced engineers and get a no-obligation quote today.

We respect your privacy — your info is safe and only used to provide your quote.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!