Product Type: Potato Chips Production Line

Output Capacity: 50 / 100 / 300 / 1000 kg/h

Power Supply: 380V / 50Hz (Customizable)

Power Consumption: 54.3 – 278.12 kW (Depending on capacity)

Applicable Materials: Potato chips, banana chips, French fries

Warranty: 2 Years

Customization: Available

Core Advantages: Automatic · Continuous Operation · Large Capacity · Fully Customizable

Description

This industrial potato chips production line is designed for the efficient production of high-quality potato chips and crisps.

Featuring high automation, energy-saving operation, and stable performance, it supports output capacities from 50 to 500 kg/h, with full customization available.

Manufactured from food-grade SUS304 stainless steel and controlled by an advanced PLC system, the line ensures safe, continuous operation.

Key components use internationally recognized brands, delivering reliable performance and long service life.

Work Flow

Fresh Potato Elevator

→ Potato Washing & Peeling Machine

→ Unqualified Potato Sorting Line

→ Potato Chips Cutting / Slicing Machine

→ Pre-Washing Elevator with Water Tank

→ Unqualified Chips Sorting Line

→ Potato Chips Washing Machine

→ Blanching Machine

→ Vibrating De-Watering Machine

→ Continuous Frying Machine

→ Vibrating De-Oiling Machine

→ Automatic Weighing & Packaging Machine

Key Advantages

Flexible Capacity & Custom Design

French fries line: 100–2000 kg/h (finished product)

Potato chips line: 50–500 kg/h (finished product)

Production process and layout can be fully customized

Food-Grade Materials & Trusted Components

All equipment made of SUS304 stainless steel

Electrical components from Schneider or CHINT

Multiple Heating Options

Electric heating

Gas heating

Diesel heating (equipped with RIELLO or BALTUR burners)

Adjustable Product Specifications

French fries size and potato chip thickness are adjustable to meet market demand

Quality Control for French Fries

Special sorting equipment to automatically remove unqualified fries

Energy-Saving Frying System

Specially designed fryer with fast heating, low energy consumption, and stable frying performance

We make things easy, reliable, and professional.

Weekly Updates: We’ll send you photos and progress reports every week.

Ready to Use: Every machine is fully built and tested for 2 hours before it leaves our factory.

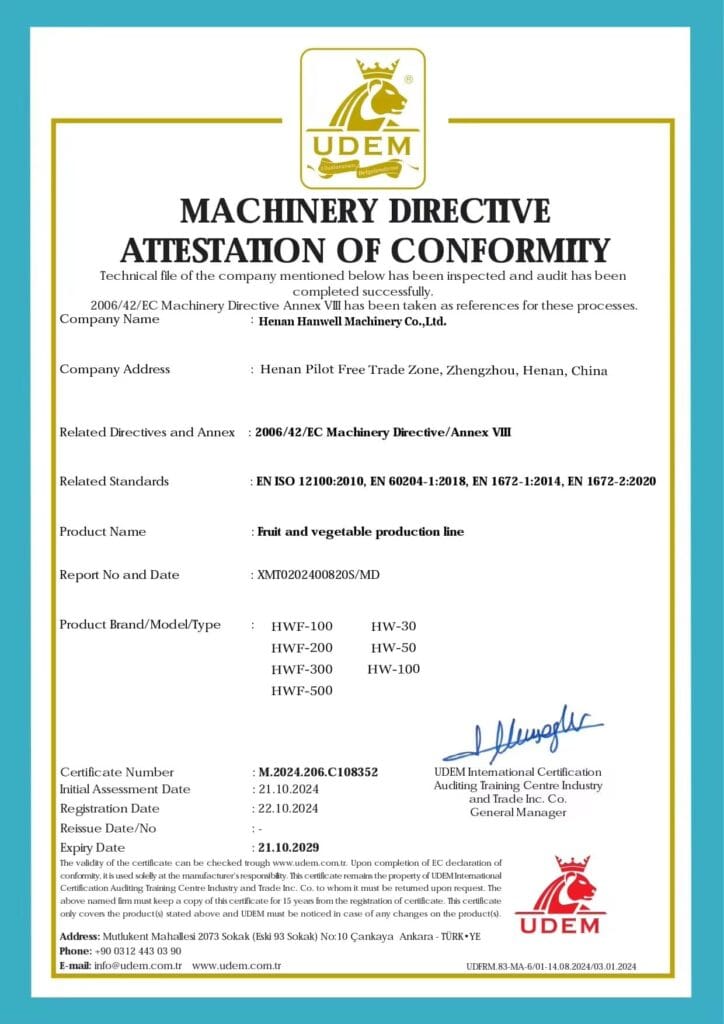

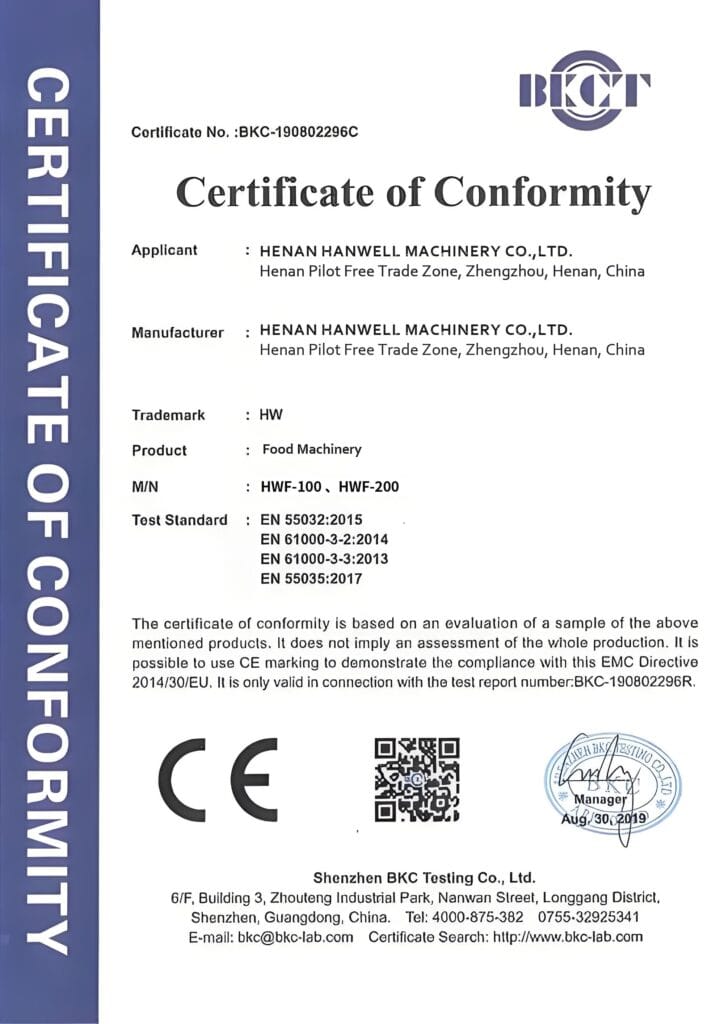

High Quality: Made entirely of top-grade stainless steel (SUS304). You are welcome to hire a third party to inspect it.

24/7 Support: We provide clear English manuals and 24-hour online help.

Expert Setup: If you need help, we can send our engineers to your site.

Future Growth: We offer OEM services, quarterly deals, and help for local agents to find customers.

Real Partnership: We visit our top clients every year to ensure your business is thriving.

Fast, customized solutions for your food production line. Talk to our experienced engineers and get a no-obligation quote today.

We respect your privacy — your info is safe and only used to provide your quote.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!