Nigeria is one of the most promising markets for snack manufacturing in Africa.

Among all local snacks, plantain chips remain one of the most consumed packaged foods across cities, schools, transportation hubs, and restaurants.

Because demand exceeds supply, many investors are now entering the industry — especially small and medium food processors.

This guide explains the market opportunity, raw materials, and machines required to start a plantain chips production business in Nigeria.

Market Opportunity: Demand Is Higher Than Production

Western fast food consumption in Nigeria continues to grow rapidly.

Alongside international restaurant chains, thousands of local eateries and street vendors sell fried snacks daily.

Current situation:

| Item | Quantity |

|---|---|

| Annual production | ~4.575 tonnes |

| Market demand | ~5.250 tonnes |

| Supply gap | Shortage exists |

This shortage creates a strong opportunity for new processing factories.

The plantain chips business is considered low risk because:

Raw materials are locally available

Consumption is daily and habitual

Shelf-stable packaged snacks sell year-round

Nigeria Plantain Production Advantage

Nigeria is one of the world’s largest plantain producers.

Production: 3,188,938 tonnes (2023 data)

Harvest area: 477,304 hectares

Major producing states include:

Lagos, Ondo, Ogun, Oyo, Osun, Ekiti, Edo, Delta, Cross River, Akwa Ibom, Imo, Bayelsa, Abia, Ebonyi

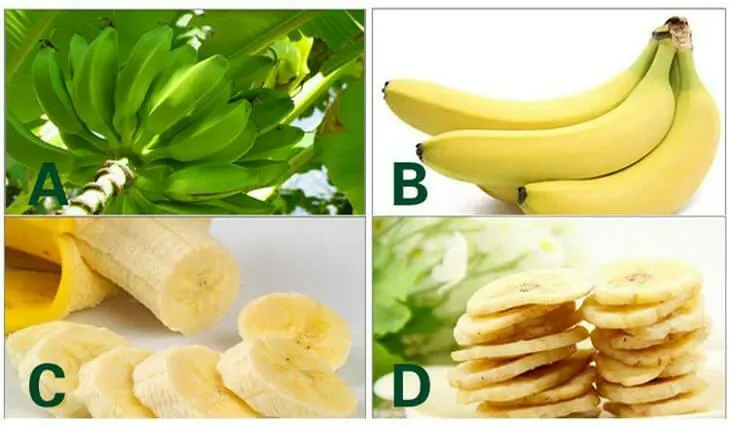

Best Plantain Varieties for Chips

Two cultivars are widely used:

French plantain – common supply

Horn plantain – preferred for chips quality & yield

The horn cultivar produces thicker, crispier chips with higher output — ideal for commercial production.

Target Market for Plantain Chips

With a population exceeding 160 million, Nigeria has a large consumer base.

Main Consumers

Urban & semi-urban residents

Students and teenagers

Office workers

Families

Bulk Buyers

Hotels

Restaurants

School canteens

Military facilities

Supermarkets & distributors

Plantain is rich in fiber and nutrients, making it a popular alternative to potato snacks and suitable for all age groups.

How Plantain Chips Are Manufactured (Industrial Process)

To operate efficiently, factories use a plantain chips production line instead of manual frying.

Processing Steps

Washing

Peeling

Slicing

Blanching

Dewatering

Frying

De-oiling

Seasoning

Packaging

Automated production improves:

Hygiene

Shelf life

Output capacity

Product consistency

Machines Required for a Small Plantain Chips Factory

A starter factory typically uses a compact continuous processing line.

Core Equipment

| Machine | Function |

|---|---|

| Plantain slicer | Uniform chip thickness |

| Blanching machine | Prevent browning |

| Dewatering machine | Remove surface water |

| Frying machine | Continuous deep frying |

| De-oiling machine | Reduce oil content |

| Flavoring tumbler | Add seasoning |

| Packing machine | Retail packaging |

Automation significantly reduces labor costs and oil consumption while increasing output stability.

Why Investors Choose Semi-Automatic Lines First

For new entrepreneurs, a small line is recommended because:

Lower initial investment

Easy operation

Expandable capacity

Fast ROI in developing markets

Production can later upgrade to a continuous industrial line once distribution channels grow.

Conclusion

Nigeria offers one of the best environments in Africa to start a snack processing factory.

Plantain chips are already widely accepted, raw materials are abundant, and demand still exceeds supply.

With the right production equipment and packaging strategy, investors can quickly establish a stable and profitable food business.

A properly planned plantain chips production line allows manufacturers to move from small startup operations to large-scale commercial supply.