China has become a global manufacturing hub for french fries processing machinery, supplying cost-effective and scalable equipment to food factories worldwide. Backed by abundant potato resources, advanced manufacturing clusters, and export-oriented suppliers, Chinese manufacturers now play a critical role in the global frozen french fries industry.

For food processors, factory owners, and project investors, understanding the major manufacturers, technologies, and market structure is essential before selecting the right production line. This guide provides a clear, objective overview of China’s french fries processing machinery landscape.

Overview of China’s French Fries Machinery Industry

China is the world’s largest potato producer, with annual output exceeding 90 million tons. This has driven rapid growth in processed potato products, especially frozen french fries used by fast-food chains, catering suppliers, and export markets.

Most french fries processing equipment manufacturers are concentrated in Shandong Province, particularly Zhucheng City, which is widely recognized as China’s main food machinery cluster. Industry estimates suggest that Zhucheng accounts for over 70% of China’s french fries processing equipment production.

Typical Equipment Characteristics

- Stainless steel (SUS304) construction for food safety

- PLC-controlled automation systems

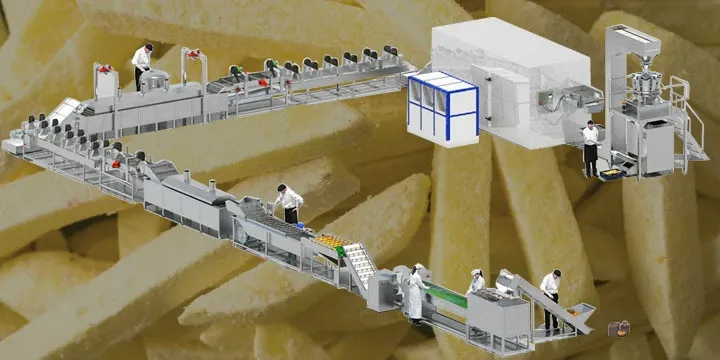

- Integrated washing, peeling, cutting, blanching, frying, de-oiling, freezing, and packaging

- Production capacities ranging from 50 kg/h to 1000 kg/h

- CE, ISO, and HACCP compliance for export markets

Market Context and Global Demand

The growth of fast-food chains, urbanization, and demand for ready-to-cook frozen foods have significantly increased the need for automated french fries production lines. Chinese manufacturers are particularly competitive in small-to-medium industrial lines, often offering prices 20–50% lower than comparable European systems.

Export markets include Africa, Southeast Asia, the Middle East, and Eastern Europe, where buyers prioritize affordability, modular expansion, and simplified maintenance.

How These Manufacturers Were Selected

There is no official or universally accepted “Top 10” ranking for french fries processing machine manufacturers in China. This list is compiled based on:

- Specialization in french fries production lines

- Range of production capacities and automation levels

- Export experience and global market presence

- Visibility in industry directories and supplier databases

- Ability to deliver complete, turnkey solutions

The focus is on practical value for B2B buyers, not marketing claims.

Top 10 French Fries Processing Machine Manufacturers in China

1. Amisy Potato Chips Machinery (Zhengzhou, Henan)

Key Products: Frozen french fries production lines (100–500 kg/h)

Strengths: Strong export focus, flexible automation, competitive pricing

Market Position: Popular among small and medium-sized processors entering international markets

Get production line details, capacity options & estimated investment directly from the manufacturer.

2. Henan Hanwell Machinery Co., Ltd. Zhengzhou, Henan)

Key Products: Fully automatic french fries plants

Strengths: Advanced PEF-assisted peeling technology, reduced water consumption

Market Position: Suitable for medium to large factories with quality-focused production

Get production line details, capacity options & estimated investment directly from the manufacturer.

3. Shandong Kexinde Machinery Technology Co., Ltd. (Jinan, Shandong)

Key Products: Industrial frozen fries lines (500–1000 kg/h)

Strengths: Energy-efficient frying systems, reliable after-sales support

Market Position: Preferred by high-capacity continuous production plants

Get production line details, capacity options & estimated investment directly from the manufacturer.

4. Henan Gelgoog Machinery Co., Ltd. (Zhengzhou, Henan)

Key Products: Modular potato processing lines, vacuum fryers

Strengths: Budget-friendly solutions, wide product range

Market Position: Ideal for startups and cost-sensitive projects

Get production line details, capacity options & estimated investment directly from the manufacturer.

5. Tonde Food Machinery Co., Ltd. (Jinan, Shandong)

Key Products: Complete french fries plants with coating systems

Strengths: Emphasis on food safety compliance and ease of operation

Market Position: Suitable for seasoned and flavored french fries production

Get production line details, capacity options & estimated investment directly from the manufacturer.

6. Anyang Romiter Machinery Co., Ltd. (Henan)

Key Products: Potato peeling, cutting, and frying systems

Strengths: Versatile designs for multiple potato products

Market Position: Common choice for processors seeking flexibility

Get production line details, capacity options & estimated investment directly from the manufacturer.

7. Shandong Shengkang Shengshi Intelligent Equipment Machinery Co., Ltd. (Zhucheng, Shandong)

Key Products: Intelligent french fries lines with drying modules

Strengths: IoT-enabled monitoring and automation integration

Market Position: Often selected by factories expanding into snack products

Get production line details, capacity options & estimated investment directly from the manufacturer.

8. Zhengzhou Lonkia Machinery Co., Ltd. (Henan)

Key Products: End-to-end potato processing solutions

Strengths: Expertise in vacuum frying and tunnel freezing

Market Position: Supports export-oriented factories with compliance needs

Get production line details, capacity options & estimated investment directly from the manufacturer.

9. Hai Rui Food Equipment Co., Ltd. (Yantai, Shandong)

Key Products: Precision peeling and sorting equipment

Strengths: R&D-driven, high-accuracy processing technology

Market Position: Favored by quality-sensitive processors

Get production line details, capacity options & estimated investment directly from the manufacturer.

10. DT Food Machine (Qingdao, Shandong)

Key Products: Custom french fries processing lines

Strengths: Short delivery cycles, scalable solutions for SMEs

Market Position: Suitable for small factories seeking fast setup

Get production line details, capacity options & estimated investment directly from the manufacturer.

Key Trends in French Fries Processing Equipment (2025–2026)

- Automation Upgrade: AI-assisted sorting and monitoring reduce labor requirements

- Energy Efficiency: Heat recovery systems and low-oil frying technologies

- Sustainability: Reduced water usage and waste management improvements

How to Choose the Right Manufacturer

Before selecting a supplier, buyers should clearly define:

- Required production capacity

- Target sales market (domestic or export)

- Automation level and labor availability

- Certification and compliance requirements

Matching the equipment to your production goals can significantly improve efficiency, product consistency, and long-term ROI.

Conclusion

China’s french fries processing machinery industry offers one of the broadest selections of automated and cost-effective production lines in the global market. While Shandong-based manufacturers dominate in volume and technology, Henan suppliers provide strong value for budget-conscious buyers.

For B2B buyers, the optimal choice depends not on brand size, but on capacity alignment, technical support, and long-term scalability. With proper evaluation, Chinese manufacturers can deliver reliable solutions for both emerging and industrial-scale french fries production.