The Development of Potato Chips Packaging Explained

Nowadays, potato chips are one of the most popular snack foods worldwide, and consumers are familiar with their colorful, lightweight packaging. However, many people still wonder: why are potato chips bags always half empty? And how did potato chips packaging develop into what we see today?

Understanding the evolution of potato chips packaging helps explain both product protection and food preservation technology.

The Development of Potato Chips Packaging

Before the invention of sealed packaging, potato chips were commonly stored in barrels or metal tins. While these containers offered basic protection, they had significant limitations. Chips stored at the bottom were often exposed to moisture, causing them to become damp and stale.

A major breakthrough came when Laura Scudder introduced an innovative packaging method. She began sealing potato chips in waxed paper bags, with the ends ironed or stapled together. This marked the beginning of sealed potato chips packaging, significantly improving freshness and shelf life.

Today, potato chips are packaged using vacuum and nitrogen-filled technology, combined with advanced packaging materials such as:

PP (Polypropylene)

PET / PC

PVC

HDPE

PS

These modern packaging solutions enable mass production, long-term storage, and global transportation of potato chips while maintaining quality.

Why Are Potato Chips Bags Half Empty?

The Truth: They Are Filled With Nitrogen

Although potato chips bags look puffy on store shelves, consumers often notice that the bag appears half empty after opening. This is because the package is intentionally filled with nitrogen gas, not air.

1. Protection Against Pressure and Crushing

If potato chips were vacuum-packed without gas, external atmospheric pressure would compress the bag, making the chips easy to break. By filling the bag with nitrogen, the internal pressure balances or exceeds the external pressure, preventing the chips from being crushed.

Additionally, pressure changes during transportation—especially when trucks pass through high-altitude regions—could cause tightly packed bags to burst if no buffer space existed.

2. Prevention of Gas Penetration

Nitrogen-filled potato chips packaging typically uses multi-layer composite films with high gas barrier properties. However, no packaging material is completely impermeable.

If the bag were vacuum-packed only, oxygen from outside would slowly penetrate, reducing shelf life. Nitrogen creates higher internal pressure, making it difficult for external air to enter the package, thereby extending the shelf life of potato chips.

3. Preservation of Freshness and Flavor

Oxygen causes oxidation, which leads to:

Rancid flavors

Texture degradation

Reduced nutritional quality

Nitrogen is an inert gas, meaning it does not react with the components of potato chips. It prevents oxidation, inhibits microbial growth, and helps preserve crispness, flavor, and freshness over time.

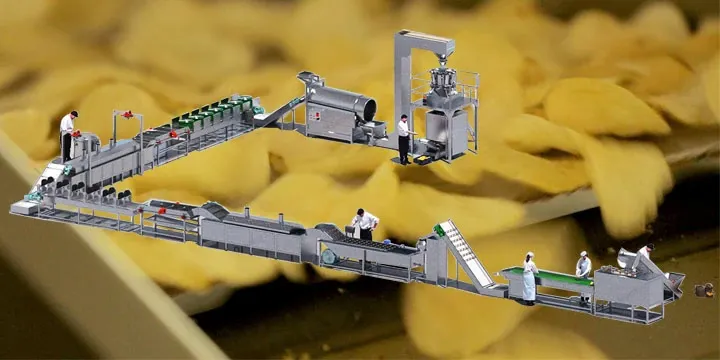

The Role of Potato Chips Packing Machines

Modern potato chips packing machines play a critical role in this process. These machines are designed to:

Extract air from the bag

Fill the bag with nitrogen

Seal the package efficiently and hygienically

This ensures potato chips remain fresh while being easy to store, transport, and distribute across long distances.

Conclusion

The half-empty appearance of potato chips bags is not a trick—it is a result of advanced food packaging technology. From early waxed paper bags to today’s nitrogen-filled composite packaging, potato chips packaging has evolved to protect freshness, prevent breakage, and extend shelf life.

By using nitrogen-filled packaging and efficient packing machines, manufacturers can deliver crispy, flavorful potato chips to consumers around the world—safe, fresh, and intact.